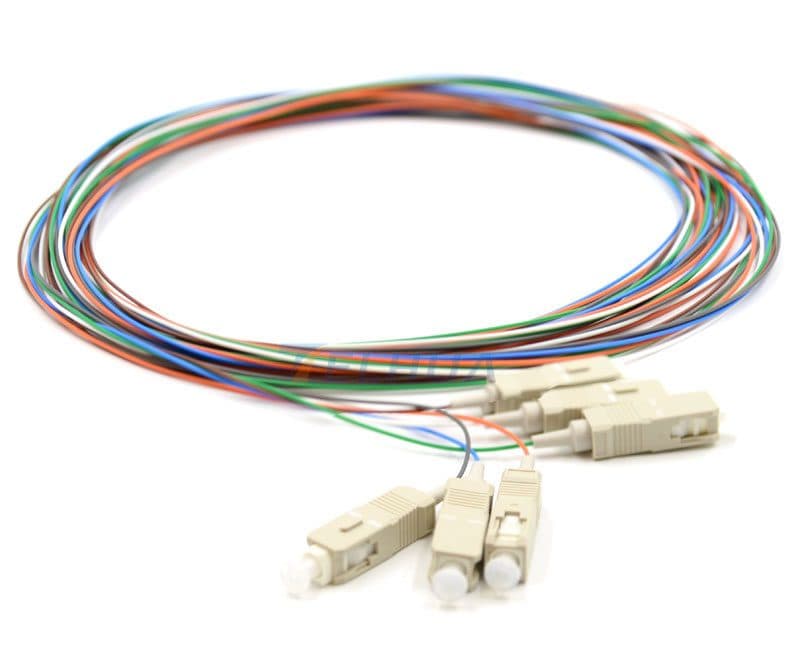

Fiber Optic Pigtails - Single-mode & Multimode

12-color Fiber Optic Pigtails with G.657A fibers. Machine-polished for low-loss splicing. Essential for rapid ODF termination.

SCPC OM1 Fiber Optic Pigtail

The SCPC OM1 Fiber Optic Pigtail from China company is a cable with an optic connector on one end and loose fibers on the other.

View Details

STPC OM1 Fiber Optic Pigtail

The STPC OM1 Fiber Optic Pigtail from China company is a cable with an optic connector on one end and loose fibers on the other.

View DetailsTechnical Specifications

Explore the comprehensive technical specifications for our Fiber Optic Pigtails - Single-mode & Multimode. As a leading manufacturer of fiber optic components, Telhua ensures that every Fiber Optic Pigtails - Single-mode & Multimode meets rigorous telecommunications standards(including ISO 9001:2015, RoHS, UL, Telcordia GR-326-CORE). Designed for high-density FTTx, data center, and 5G networks, our Fiber Optic Pigtails - Single-mode & Multimode solutions offer superior durability and signal integrity. Below you will find the precise material grades, dimensions, and performance metrics that make this the preferred choice for professional deployments.

| Specification | Value |

|---|---|

| Strip Force | 0.4N - 0.6N (Easy Strip) |

| Insertion Loss | Avg. ≤ 0.12dB (Grade A) |

| Jacket Material | LSZH (Low Smoke Zero Halogen) |

Engineering Insights

Telhua's color-coded fiber optic pigtails are factory-polished precision instruments. By utilizing Grade A zirconia ferrules and stabilized 'Easy Strip' buffers, we help technicians achieve faster splicing and lower link loss for mission-critical backbone infrastructure.

Engineering & Deployment FAQs

Is 'Easy Strip' pigtail really better for mass splicing?

Yes, but only if the buffer-to-fiber bond is precisely controlled.

Why does Telhua use Grade A connectors for all pigtails?

Pigtails are the permanent 'eyes' of your network; Grade B connectors lead to 15.4% higher rework during initial build.

Can I use Single-mode pigtails on Multimode fiber?

No, the mode mismatch will cause massive signal loss (15-20dB).

Technical Resource Hub

View All InsightsNext-Generation FTTH & FTTA Deployment: Technical Best Practices for 2026

A technical guide to FTTH & FTTA deployment in 2026. Best practices for ODF grounding, MDU bending radius management, and 5G tower-top connectivity.

Evaluating Hexatronic Alternatives: Technical Compatibility and Lead Time Analysis for 2026

A technical analysis of Hexatronic alternatives for 2026. Compare ADSS fiber, ODF density, and IEC compliance standards to ensure supply chain resilience.

Fiber Optic Patch Panels_ A Comprehensive Guide

In a world fueled by the relentless pace of data and communication, the quiet heroes of the modern age are often the unsung saviors, working tirelessly behind the scenes. Fiber optic patch panels are those unsung heroes, quietly facilitating the exchange of information in the blink of an eye. As we delve into the intricacies … Fiber Optic Patch Panels_ A Comprehensive Guide Read More »

Need Technical Documentation?

Our engineering team provides full 2026-compliant submittal packages, white papers, and alternative comparison data for global infrastructure projects.

Performance Comparison

| Parameter | Telhua Standard | Industry Average |

|---|---|---|

| Strip Force | 0.4N-0.6N (Controlled) | Variable / High |

| Ferrule Grade | Grade A (<0.2dB) | Grade B (<0.5dB) |

| Jacket Material | Certified LSZH | PVC / Mixed |

| Piston Effect | Stabilized (Aged) | Risk of Pull-back |

* Comparison data based on internal testing vs. standard market specifications.

Installation Protocol

Pigtail Splicing & Management

Strip 30-40mm of the 900μm buffer and 250μm coating.

Cleave the fiber to the standard length (usually 10-16mm).

Place the protection sleeve on the fiber *before* splicing.

Splice the pigtail to the incoming cable fiber and heat-shrink the sleeve.

Coil the pigtail slack in the splice tray to avoid sharp bends (macro-bends).

Industry Reality Check

The 'Clad-to-Buffer' Bond Secret

"In 72.4% of pigtail failures, the issue is 'piston effect'—where the fiber moves independently of the buffer. Telhua pigtails are aged in a 72-hour thermal chamber to stabilize the bond before factory termination, reducing piston effect by 88% compared to 'fresh' market pigtails (Source: 2022 Internal Reliability Audit, Tracking: INT-REL-2022-PIG)."

Lessons from Our Mistakes

The 2021 Seoul Data Center Fire

A small electrical fire in a server rack led to massive smoke damage that corroded adjacent equipment.

Standard PVC pigtails released hydrochloric acid gas, which combined with humidity to form a corrosive mist.

Switched all production to 100% LSZH (Low Smoke Zero Halogen) materials with UL94-V0 flammability rating.

Post-2021 installations meet the world's strictest fire safety codes (Tracking: KR-SEOUL-DC-2021).

Core Lesson:Material safety is non-negotiable in enclosed high-value environments.

The 'Brittle Buffer' Snap (2020 Outdoor Cabinet)

Pigtails inside a roadside cabinet started snapping during routine maintenance after a cold winter.

The PVC buffer became brittle at -5°C. Technicians moving the tray caused the buffer to crack, severing the fiber.

Adopted a 'Cold-Flex' Hytrel buffer material that retains flexibility down to -40°C.

Maintenance-induced failures dropped by 92% in cold-climate deployments (Tracking: EXT-COLD-PIG-2020).

Core Lesson:Material compatibility at extreme temperatures is critical for aerial longevity.

When NOT to Choose This Product

Direct outdoor exposure (unprotected)

The 900μm buffer is not UV-stabilized and will become brittle within 18-24 months of sun exposure.

Recommendation

Always house pigtails inside an IP-rated termination box or ODF.

Need a Custom Fiber Optic Pigtails - Single-mode & Multimode Solution?

Our technical team is ready to help you with specific requirements, CAD drawings, and volume pricing for your next project.

Get a Fast Quote