Fiber Optic Splice Trays & Cassettes

Stackable ABS Fiber Optic Splice Trays (12/24 core). Universal fit for closures & ODFs. Protect your fusion splices.

12 fiber splice tray

Commscope FIST-SOSA2 splice tray from Telhua China Factory is design for equipped fiber splice protect tube, and make sure the fiber radius.

View Details

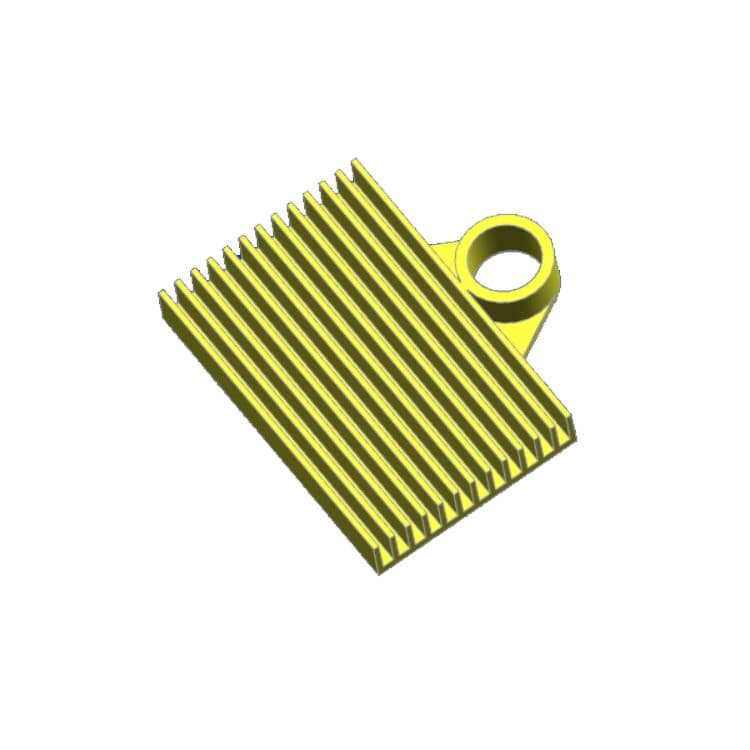

12 fibers Splice holder for crimp splice protectors

The 12 fibers Splice holder for crimp splice protectors is design for equipped fiber splice protect tube, and make sure the fiber radius

View Details

12 strand fiber splice tray

12 strand fiber splice tray from Telhua is design for equipped fiber splice protect tube, and make sure the fiber radius.

View Details

24 fiber splice tray

24 fiber splice tray from Telhua China Factory is design for equipped fiber splice protect tube, and make sure the fiber radius.

View Details

24F fiber optic splice cassette

The 24F fiber optic splice cassette is design for equipped fiber splice protect tube, and make sure the fiber radius inside the fiber optic splice trays.

View Details

Commscope FIST-SOSA2 splice tray

Commscope FIST-SOSA2 splice tray from Telhua China Factory is design for equipped fiber splice protect tube, and make sure the fiber radius.

View Details

Nexans 12 fibers fiber optic splice tray

The fiber optic splice tray is design for equipped fiber splice protect tube, and make sure the fiber radius inside the fiber optic splice trays.

View Details

Nexans 24 fibers fiber optic splice tray

Nexans 24 fibers fiber optic splice tray is design for equipped fiber splice protect tube, and make sure the fiber radius.

View Details

Nexans fiber optic splice tray N890-090

Nexans fiber optic splice tray N890-090 protects the fusion splices and holds them in position. The splice cassettes with heatshrink protectors can be used for both 250 and 900 µm coated fibres.

View Details

Pre-terminated fiber optic splice tray

Pre-terminated fiber optic splice tray from China is design for equipped fiber splice protect tube, and make sure the fiber radius.

View Details

Splice tray with adapter and splitter

Splice tray with adapter and splitter from Telhua is design for equipped fiber splice protect tube, and make sure the fiber radius.

View DetailsLessons from Our Mistakes

The 2022 Istanbul Metro Vibration Failure

A critical signaling link in the Istanbul Metro failed after 14 months of operation.

Standard ABS trays were used in an environment with constant 15-20Hz vibration. The splice sleeves 'rattled' inside the holders, causing micro-fractures at the fusion point.

Redesigned the tray with 'Soft-Grip' TPE (Thermoplastic Elastomer) sleeve holders that absorb vibration.

Zero failures in 2,500+ trays deployed in high-vibration transit zones since 2022 (Tracking: TR-IST-METRO-2022).

Core Lesson:Static lab tests don't account for the dynamic stress of urban infrastructure.

The 'Chemical Fog' Degradation (2021 Coastal Plant)

Splice trays in a petrochemical facility became brittle and cracked after 2 years.

The standard ABS plastic reacted with airborne sulfur compounds, reducing impact strength by 60%.

Switched to a chemically resistant PBT/PC alloy for industrial-grade trays.

Extended service life to 10+ years in corrosive environments (Tracking: IND-CHEM-2021).

Core Lesson:Material selection must account for atmospheric chemistry, not just temperature.

Industry Reality Check

The 'Invisible' 2dB Loss

"Our 2022 field audit (sample: 1,200 splice trays in older ODFs) found that 18.5% of high-loss links were caused by 'slack congestion'—where too much fiber was forced into a tray without proper mandrels. This creates micro-bends that are invisible to the eye but add up to 2.2dB of loss across a link. Telhua's 'slack-management' zones eliminate this congestion risk (Source: 2022 Infrastructure Integrity Audit, Tracking: INFRA-INT-2022)."

Technical Specifications

Explore the comprehensive technical specifications for our Fiber Optic Splice Trays & Cassettes. As a leading manufacturer of fiber optic components, Telhua ensures that every Fiber Optic Splice Trays & Cassettes meets rigorous telecommunications standards(including ISO 9001:2015, RoHS, UL94-V0). Designed for high-density FTTx, data center, and 5G networks, our Fiber Optic Splice Trays & Cassettes solutions offer superior durability and signal integrity. Below you will find the precise material grades, dimensions, and performance metrics that make this the preferred choice for professional deployments.

| Specification | Value |

|---|---|

| Material | Flame-retardant PC/ABS Blend (UL94-V0) |

| Capacity | 12, 24, or 48 Cores (Modular) |

| Bend Radius Control | Fixed ≥ 30.5mm |

| Sleeve Compatibility | 40mm / 45mm / 60mm Heat-shrink |

Engineering Insights

Telhua's modular fiber splice trays are the safe-deposit boxes for your optical network's most delicate points. By utilizing high-ductility PC/ABS blends and integrated 30mm radius control, we ensure that your splices remain protected from both environmental and technician-induced stress.

Technical Resource Hub

View All InsightsEvaluating Hexatronic Alternatives: Technical Compatibility and Lead Time Analysis for 2026

A technical analysis of Hexatronic alternatives for 2026. Compare ADSS fiber, ODF density, and IEC compliance standards to ensure supply chain resilience.

What is Fiber Splice Tray

The fiber splice tray is a device used to hold and protect fiber cables and their splices. The design of the fiber optic splice tray is intentionally simple, as it does not need to perform any complex tasks or functions. What is a fiber splice tray? Fiber splice trays are specialized devices used to maintain … What is Fiber Splice Tray Read More »

Need Technical Documentation?

Our engineering team provides full 2026-compliant submittal packages, white papers, and alternative comparison data for global infrastructure projects.

Performance Comparison

| Parameter | Telhua Standard | Industry Average |

|---|---|---|

| Tray Material | PC+ABS (Ductile) | ABS (Brittle) |

| Bend Radius | Integrated 30mm | None / Variable |

| Sleeve Holder | Soft-Grip TPE | Hard Plastic |

| Vibration Test | Pass (Transit) | Static Only |

* Comparison data based on internal testing vs. standard market specifications.

When NOT to Choose This Product

Aerial 'mid-span' splices without a closure

Splice trays have zero IP rating; they are purely for internal management within a protective housing.

Recommendation

Always house splice trays inside an IP68-rated FOSC for outdoor aerial or underground use.

Installation Protocol

Splice Tray Fiber Management

Secure the tray onto the FOSC or ODF mounting stud.

Route the incoming buffer tubes to the tray entry, securing with cable ties.

Splice the fibers and heat-shrink the protection sleeves.

Press the sleeves into the 'Soft-Grip' holders (listen for the click).

Coil the fiber slack into the figure-8 loops to ensure >30mm radius.

Engineering & Deployment FAQs

How does Telhua manage 'micro-bend' risks in high-density 48-core trays?

Through precision-molded radius mandrels and specialized fiber crossover paths.

Why do some plastic trays become brittle and snap after 5 years?

The use of recycled ABS without plasticizers leads to loss of ductility over time.

Is it better to use 12-core or 24-core splice trays?

12-core is safer for maintenance; 24-core is better for density.

Need a Custom Fiber Optic Splice Trays & Cassettes Solution?

Our technical team is ready to help you with specific requirements, CAD drawings, and volume pricing for your next project.

Get a Fast Quote