Fiber optic patch panel production line – Telhua

Originally Published: November 25, 2019 by Blair Haas. Enhanced and Updated for 2026 by Telhua’s Industry Experts.

Introduction: The Shift Towards Larger, Lighter, Stronger Enclosures

For years, the electronics industry has been dominated by the narrative of miniaturization. While components have indeed become smaller, a counter-trend is emerging as a critical factor for innovation in 2026: the consolidation of complex systems. Products that once required sprawling, multi-bay metal cabinets can now be integrated into a single, extra-large enclosure. This shift demands solutions that are not only spacious but also lightweight, durable, and resilient against harsh environments.

Historically, designers defaulted to metal for large-scale applications, assuming it was the only option for strength and security. However, this assumption is now outdated. Significant investments in polymer science and manufacturing technology have made extra-large plastic enclosures not just a viable alternative, but often the superior choice. The reduction in weight, superior impact resistance, inherent corrosion-proof properties, and design flexibility of advanced plastics are game-changers. [13, 20]

At Telhua, we are at the forefront of this evolution. We are proud to introduce the Telhua NBG Series, a line of extra-large electronic enclosures engineered for the demands of 2026 and beyond. Crafted from an advanced PC+PBT (Polycarbonate + Polybutylene Terephthalate) blend, these enclosures deliver unparalleled strength, weather resistance, and the certified protection of NEMA 4x and IP66 ratings. [9, 11] This article will serve as your definitive guide to understanding why these enclosures are essential for the next wave of technological advancement.

2026 Industry Trends Demanding Advanced Enclosure Solutions

The need for large, robust, and non-metallic enclosures is being driven by major technological shifts. As we look at the landscape of 2026, several key sectors are pushing the boundaries of what’s possible, requiring infrastructure that can keep pace.

1. 5G and Edge Computing Infrastructure

The rollout of 5G and the rise of edge computing require deploying sensitive electronic equipment in more outdoor and remote locations than ever before. [38] These installations, which house everything from base station electronics to edge data processors, must be protected from the elements. Large plastic NEMA 4x enclosures are ideal for housing these consolidated systems, offering excellent protection against rain, dust, and temperature fluctuations without interfering with RF signals—a significant advantage over metal. [28] The lightweight nature of plastic also simplifies installation on towers and rooftops.

2. Renewable Energy and Battery Storage

The global push for green energy has led to a boom in solar, wind, and battery energy storage systems (BESS). [29, 31] These installations are, by nature, exposed to the harshest outdoor conditions. [25, 33] Large PC+PBT enclosures are critical for protecting inverters, charge controllers, and battery management systems. [25] Their NEMA 4x rating ensures resistance to corrosion, a major issue in coastal and industrial areas, while their size accommodates the increasingly complex and powerful components of modern energy systems. [7, 31]

3. Industrial IoT (IIoT) and Automation

Smart factories and Industry 4.0 initiatives involve deploying a vast network of sensors, controllers, and communication hubs. [12] Consolidating the controls for an entire robotic cell or a section of a production line into a single, large enclosure simplifies installation and maintenance. A non-metallic PC+PBT enclosure is often preferred in these environments to resist chemical washdowns and prevent electrical conductivity risks, enhancing workplace safety. [20, 22]

4. Smart Transportation and EV Charging

Intelligent transport systems and the explosive growth of electric vehicle (EV) charging stations require durable outdoor enclosures. [29] These units house control systems, power distribution hardware, and communication modules that must operate reliably in all weather. Large plastic enclosures provide a lightweight, corrosion-proof, and aesthetically flexible housing solution perfect for public and roadside installations. [32]

Plastic vs. Metal in 2026: A Clear Winner Emerges

While metal enclosures have their place, the advantages of advanced plastics like Telhua’s PC+PBT blend are becoming undeniable for large-scale applications in 2026.

- Corrosion Resistance: This is the most significant advantage. Plastic does not rust or corrode. A NEMA 4x rating on a plastic enclosure means it is inherently corrosion-proof, whereas a metal enclosure requires special (and often costly) coatings to achieve the same resistance. [2, 5, 7] This makes plastic the only logical choice for coastal, marine, and chemical-heavy environments. [4]

- Weight: A large plastic enclosure can be up to 50% lighter than its steel equivalent. [22] This drastically reduces shipping costs, simplifies installation (often allowing for a one-person job instead of two), and reduces the structural load on walls and poles.

- Impact Resistance: The PC+PBT blend used in the Telhua NBG series offers exceptional impact strength, absorbing shocks that would dent or deform a metal enclosure. [17, 18] This ensures the integrity of the seal and the protection of the components inside.

- RF Transparency: For the growing number of IoT and 5G applications, plastic enclosures do not block or interfere with Wi-Fi, Bluetooth, or cellular signals. [13] Metal enclosures require external antennas, adding complexity and potential points of failure.

- Cost and Customization: Plastic is often more affordable, especially when considering the total cost of ownership (installation, maintenance, and lifespan). [20] It is also easier to machine and modify, allowing for quick and clean cutouts for cables, displays, and controls. [13]

2026 Global Supplier Comparison: Why Telhua Leads the Pack

When selecting an enclosure partner, it’s crucial to look beyond the product to the company’s innovation, support, and readiness for future trends. Here’s how Telhua compares to other major suppliers in the market.

| Feature | Telhua | Supplier A (e.g., Fibox) [1] | Supplier B (e.g., Bud Industries) [1] | Supplier C (e.g., Bison Profab) [1, 6] |

|---|---|---|---|---|

| Primary Material Focus | Advanced PC+PBT Blends for 2026+ applications | Polycarbonate | Broad range (Plastic, Steel, Aluminum) | Primarily Metal (Steel, Aluminum) |

| Extra-Large Size Availability | Industry-leading range in the NBG Series | Good range, but more limited at the largest sizes | Available, but often in traditional materials | Custom metal fabrication focus |

| Material Innovation (UV, Chemical Resistance) | (f1) rated PC+PBT for superior weatherability and durability [9, 11] | Strong UV resistance in polycarbonate | Standard material options | Focus on metal coatings |

| NEMA 4x / IP66 Certification | Standard across the NBG series [36, 37] | Widely available | Available on specific product lines | Standard for outdoor metal enclosures |

| Focus on 2026 Trends (IoT, Renewables) | Core market focus with dedicated solutions | Strong presence in industrial controls | General-purpose electronics focus | Focus on traditional electrical and traffic cabinets |

As the table shows, while other suppliers offer quality products, Telhua is uniquely positioned with a forward-looking strategy, focusing on the advanced materials and sizes required for the key growth sectors of 2026.

Professional Technical Selection Guide for Large Enclosures

Choosing the right enclosure is a critical design decision. Follow this professional guide to ensure you select the perfect solution for your project.

Step 1: Understand the Ratings – NEMA 4x vs. IP66

While often seen together, these ratings are not identical. [5]

- IP66: An international standard (IEC 60529) that specifies protection against “powerful water jets and complete protection against dust ingress. [3, 4]

- NEMA 4x: A North American standard (NEMA 250) that includes all the protection of IP66 but adds a crucial element: corrosion resistance. [2, 3] It also provides protection against damage from external ice formation. [3]

Pro-Tip: If your application is outdoors, in a coastal area, or in an industrial facility with chemicals, the ‘x’ in NEMA 4x is non-negotiable. Telhua’s PC+PBT material is inherently corrosion-resistant, making it a perfect fit for NEMA 4x requirements. [5]

Step 2: Material Matters – PC+PBT is the Future

Not all plastics are created equal. While materials like ABS are common, they are not suitable for demanding outdoor use. [28] Telhua’s choice of a PC+PBT blend provides a superior combination of properties:

- Strength & Stiffness (from PBT): Ensures the enclosure holds its shape and can support internal mounting plates and heavy components. [9]

- Impact & Temperature Resistance (from PC): Provides incredible toughness, even at low temperatures, and maintains dimensional stability in the heat. [17, 18]

- Chemical Resistance (from PBT): Protects against oils, solvents, and other industrial chemicals. [18]

- UV Resistance: Our blend is specifically formulated with UV stabilizers for long-term outdoor performance without becoming brittle. [11]

Step 3: Sizing and Thermal Management

When selecting a size, plan for the future. Allow at least 25% extra space for future upgrades, wiring, and airflow. Heat is the enemy of electronics. [26] While plastic is an insulator, thermal management is still crucial. [13, 10]

- Passive Cooling: For low-power applications, the large surface area of the enclosure may be sufficient. Consider adding vents or louvers. [23]

- Active Cooling: For high-power components, plan for the integration of fans, heat exchangers, or even enclosure air conditioners. Telhua can provide custom cutouts for these devices.

Recent advancements in thermally conductive plastics are also creating new possibilities for passive heat dissipation directly through the enclosure body. [19, 24]

Step 4: Plan for Customization

Your enclosure is part of your product. Telhua offers comprehensive customization services to save you time and effort, including:

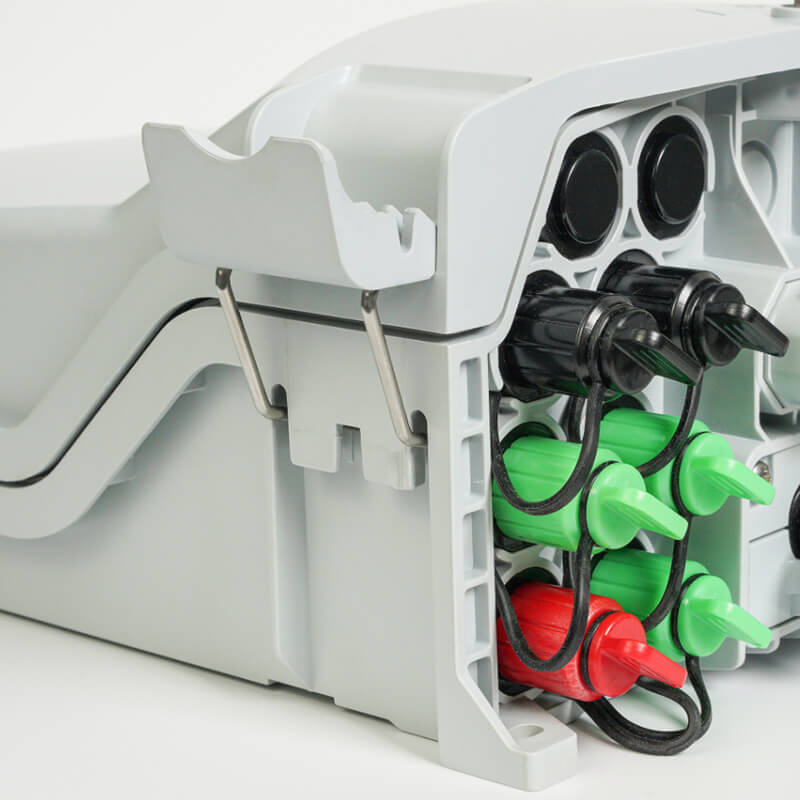

- Precision CNC cutouts for displays, buttons, connectors, and glands.

- Custom-fit internal mounting plates.

- Screen printing for branding, logos, and safety information.

- A wide range of accessories like cable glands, vents, and locking mechanisms.

Frequently Asked Questions (FAQ)

- 1. Can a large plastic enclosure really be as strong as metal?

- Yes, and in some ways, it’s better. While metal has higher tensile strength, it deforms on impact (denting), which can compromise the seal. The high-impact PC+PBT used in Telhua’s NBG series is designed to absorb significant impact and return to its original shape, maintaining the NEMA 4x seal. [17, 27]

- 2. How do you handle heat dissipation in a plastic enclosure?

- Thermal management is key. [26] For many modern electronics with low to moderate heat output, the large surface area of the enclosure combined with proper component spacing is sufficient. For higher heat loads, we recommend and can provide cutouts for vents, fans, or thermoelectric coolers. The key is to calculate your thermal load and plan accordingly. [23]

- 3. What is the UV resistance of Telhua’s PC+PBT enclosures?

- The Telhua NBG series is made from an (f1) rated material, which is a UL designation indicating it has passed rigorous testing for UV exposure and water immersion, making it suitable for outdoor use. [11] This ensures the material won’t degrade or become brittle even after years in direct sunlight. [35]

- 4. Is it difficult to drill or make cutouts in these enclosures?

- No, it’s significantly easier and safer than with metal. [20] PC+PBT can be cleanly machined without the sharp edges, burrs, or need for finishing that metal requires. For perfect, factory-quality results, we highly recommend using Telhua’s customization services.

- 5. How secure are Telhua’s large plastic enclosures?

- Security is a priority. The NBG series features robust construction and multiple locking options, including pad-lockable latches and key-lock inserts. As we move into 2026, we are also exploring the integration of smart locking technologies like NFC for enhanced, digitally-managed access control. [21]