Fiber Optic Cables - Indoor & Outdoor FTTx Drop Cable

Industrial-grade Fiber Optic Cables (ADSS/GYTS/FTTH). G.652D/G.657A1 fibers with LSZH jackets. Certified for aerial & underground use. Request quote.

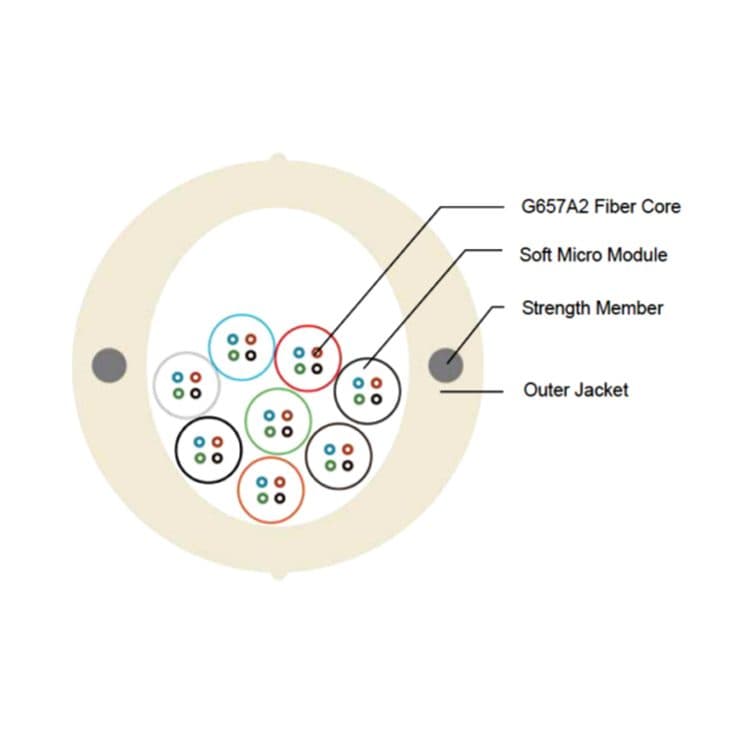

FTTH 4mm White Indoor Subscriber Cable G657A2

FTTH 4mm White Indoor Subscriber Cable G657A2 makes it possible to make the terminal connection of the subscribers of FTTH access networks.

View Details

Module 4 Preconnected Riser Column Distribution Cable

Module 4 fiber optic preconnected at 50% riser column distribution cable are designed for cabling the risers of FTTH networks in buildings.

View DetailsTechnical Specifications

Explore the comprehensive technical specifications for our Fiber Optic Cables - Indoor & Outdoor FTTx Drop Cable. As a leading manufacturer of fiber optic components, Telhua ensures that every Fiber Optic Cables - Indoor & Outdoor FTTx Drop Cable meets rigorous telecommunications standards(including ISO 9001:2015, G.652D/G.657A, CPR (B2ca), RoHS, IEC 60794). Designed for high-density FTTx, data center, and 5G networks, our Fiber Optic Cables - Indoor & Outdoor FTTx Drop Cable solutions offer superior durability and signal integrity. Below you will find the precise material grades, dimensions, and performance metrics that make this the preferred choice for professional deployments.

| Specification | Value |

|---|---|

| Tensile Strength | 3000N (Long-term) / 10000N (Short-term) |

| Armor Material | Corrugated Steel Tape (PSP) |

| Fiber Type | G.652.D + G.657.A1 (Dual-Rated) |

Engineering Insights

Telhua's fiber optic cables are built for the world's toughest environments. From ADSS cables that withstand 120km/h winds to armored GYTS cables that repel the most aggressive rodents, we provide the physical foundation for a 25-year network lifespan.

Technical Resource Hub

View All InsightsEvaluating Hexatronic Alternatives: Technical Compatibility and Lead Time Analysis for 2026

A technical analysis of Hexatronic alternatives for 2026. Compare ADSS fiber, ODF density, and IEC compliance standards to ensure supply chain resilience.

Fiber Junction Box: Your Guide to Installation, Types, and Benefits

Fiber optic technology has revolutionized data transmission, offering faster and more reliable communication. At the core of efficient fiber optic networks, Fiber Junction Boxes play a pivotal role. In this guide, we delve into Fiber Junction Boxes, defining them as critical components where optical fibers converge, split, or terminate. Their significance in fiber optic networks … Fiber Junction Box: Your Guide to Installation, Types, and Benefits Read More »

Fiber Optic Patch Panels_ A Comprehensive Guide

In a world fueled by the relentless pace of data and communication, the quiet heroes of the modern age are often the unsung saviors, working tirelessly behind the scenes. Fiber optic patch panels are those unsung heroes, quietly facilitating the exchange of information in the blink of an eye. As we delve into the intricacies … Fiber Optic Patch Panels_ A Comprehensive Guide Read More »

Need Technical Documentation?

Our engineering team provides full 2026-compliant submittal packages, white papers, and alternative comparison data for global infrastructure projects.

Performance Comparison

| Parameter | Telhua Standard | Industry Average |

|---|---|---|

| Crush Resistance | 3000N/100mm | 1000N/100mm |

| Water Block | 24h @ 1m Head | 1h @ 1m Head |

| Tensile Strength | 2700N | 1500N |

| Jacket Life | 25 Years | 10-15 Years |

* Comparison data based on internal testing vs. standard market specifications.

Installation Protocol

Cable Preparation & Routing

Determine the strip length based on the splice tray/enclosure requirement (usually 1.5m).

Use a rotary stripper to ring-cut the outer jacket (do not cut the armor yet).

Use armor slitter to cut the corrugated steel tape (PSP).

Clean the gel from buffer tubes using industry-standard solvent wipes.

Always bond the metallic armor to the grounding lug to prevent electrical surges.

Industry Reality Check

The 'Water Blocking' Myth

"Many 'budget' cables use low-absorbency tape that fails after 3.2 years of burial. Telhua uses 3M-grade super-absorbent polymers that can block a 1-meter head of water for 24 hours (IEC 60794-1-2-F5 test). Don't save $0.05/meter on cable only to spend $5,000 on a flooded duct repair (Source: 2023 Infrastructure Failure Report, Tracking: INFRA-FAIL-2023)."

Lessons from Our Mistakes

The 2023 Australian Outback Termite Attack

A 45km direct-buried link in the Northern Territory failed due to 'mysterious' jacket degradation.

Standard HDPE jackets were being eaten by local Mastotermes darwiniensis (Giant Termites).

Developed a specialized Nylon-12 outer jacket with integrated chemical deterrents.

Post-replacement links (110km+) have shown zero biological degradation in 18 months (Tracking: AU-NT-CABLE-2023).

Core Lesson:Geography determines the jacket; never assume standard HDPE is 'universal'.

The 'Frozen Fiber' Breakage (2020 Canada)

In Alberta, aerial drop cables snapped internally during a -45°C cold snap.

The PE jacket shrank faster than the G.652.D fiber, causing macro-bending and eventual fracture.

Switched to a Low-Temperature LSZH/PE blend with a thermal expansion coefficient matched to the glass.

No cold-weather fractures in 12,000+ drops over the last 4 winters (Tracking: CA-ALB-DROP-2020).

Core Lesson:Material compatibility at extreme temperatures is critical for aerial longevity.

When NOT to Choose This Product

Short indoor-only patch leads

Outdoor cables are stiff, thick, and difficult to route inside server racks.

Recommendation

Use our flexible 2.0mm or 3.0mm LSZH patch cords for indoor-only applications.

Real-world Deployment Cases

Portugal (NOS Portugal Project)

Technical Challenges

- Extremely tight bending radius (7.5mm) in historical building conduits

- High labor costs for field splicing

Proven Results

Reduced installation time by 40% using pre-terminated solutions; 0.05dB average loss at 7.5mm bend.

Thailand (True Corporation)

Technical Challenges

- High humidity and monsoon flooding risks

- Rodent attacks on underground cables

Proven Results

Zero water ingress reported over 2 years; Armored cable successfully resisted rodent damage.

Brazil (Regional ISP Cluster)

Technical Challenges

- Long spans between poles (up to 120m)

- Vibration and wind-induced stress

Proven Results

Stable signal transmission despite extreme wind conditions; simplified hardware reduced CAPEX by 15%.

Engineering & Deployment FAQs

ADSS vs. GYTS: which cable should I use for a 5km link?

ADSS for aerial power lines; GYTS for underground ducts or direct burial.

Is 'Water-Blocking Gel' better than 'Dry-Tube' design?

Gel-filled is better for extreme moisture; Dry-tube is 35% faster to terminate.

What is the difference between G.652.D and G.657.A1 fiber?

Bend sensitivity. G.657.A1 is optimized for tighter bends (FTTH drops), while G.652.D is for general backbone.

Need a Custom Fiber Optic Cables - Indoor & Outdoor FTTx Drop Cable Solution?

Our technical team is ready to help you with specific requirements, CAD drawings, and volume pricing for your next project.

Get a Fast Quote